![Infrared Camera [InfReC]](/jp/products/ir-thermo/images/infrec-logo.jpg)

[InfReC] is the coined abbreviation word of "Infrared Camera" and also has the meaning of [The Device Recording Infrared Information].

Our product research and development is targeted at improving the quality of life by protecting people and simplifying their daily tasks while measuring temperature, controlling environments, enhancing security, etc.

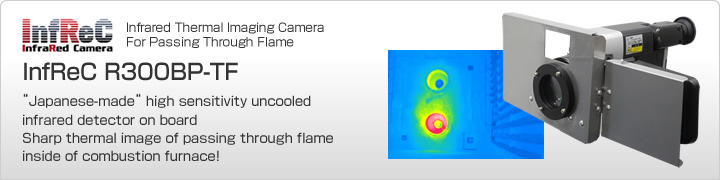

InfReC R300BP-TF

Discontinued Models

Infrared Thermal Imaging Camera for Passing Through Flame

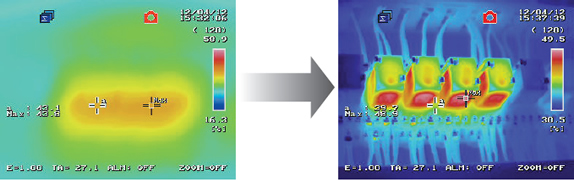

Sharp thermal image of passing through flame inside of Coal and Oil refinery furnaces

"R300BP-TF" is the most effective infrared thermal imaging camera to find out the state of adhered clinker and diagnosing deterioration of internal facility of furnace.

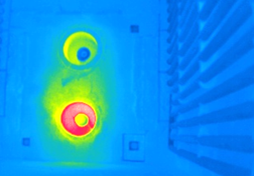

- Visible image of burner

The burner behind flame is invisible.

- Thermal image of burner

Temperature distribution of burner through flame is visible.

Maintenance-free operation thanks to "Japanese-made" Uncooled infrared detector!

"R300BP-TF" detects infrared ray in the "Short-wavelength" region, between 3.7µm and 3.9µm, by the combination of "Japanese-made" high sensitivity Uncooled infrared detector with 3.8µm passing-through-flame filter.

As a result, the new model "R300BP-TF" features significantly reduced price and maintenance-free operation in comparison with the conventional model equipped with cooled infrared detector. You can use "R300BP-TF" without worrying about lifetime and maintenance cost of cooling detector.

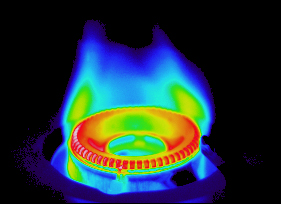

General Uncooled Infrared Camera

In the wavelength range (8µm to 14 µm) of the general uncooled infrared detector, the influence of flame is clearly present.

R300BP-TF

By stretching the sensitivity of the "Japanese-made" uncooled detector to the short-wavelength region, it is possible to eliminate the flame influence by using a 3.8µm passing-through-flame filter.

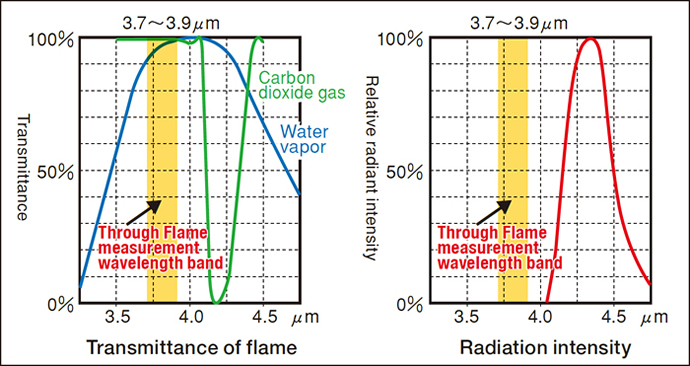

The principle of measurement Through Flame and Feature points of R300BP-TF

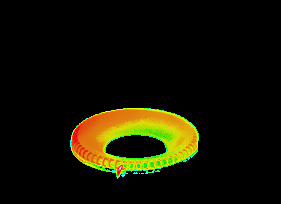

When fuel gas (Hydrocarbon Gas) burns, the infrared energy radiates from not only flame but also H2O and CO2.

For above condition, taking thermal image passing through flame by infrared thermal imaging camera (IR camera) is required following conditions;

- Select absorb-less band of wavelength by Gas (CO2 and water vapor) that is generated when fuel gas burns.

- Select wavelength band as far away from Flame Infrared Energy radiant intensity wavelength as possible.

- Use infrared detector, which has sensitivity with above wavelength band.

Therefore, the suitable wavelength band for taking thermal image passing through flame is 3.8µm wavelength band.

Generally, this wavelength band is detected by cooled type infrared detector, however, this type IR camera is very expensive and its cooler requires maintenance at constant time usage.

Avio achieved success to stretching sensitivity to short-wavelength band by "Japanese-made" Uncooled type infrared detector. Herewith, we realized to reducing-cost and maintenance-free of R300BP-TF.

- *Note: Depending on combustion gas kinds, R300BP-TF has possibility that cannot eliminate flame, and it influence to measuring result. We recommend to test by Demo-Unit before purchasing.

User-Friendly operability and mobility

Making a quick measurement even under harsh measurement environments

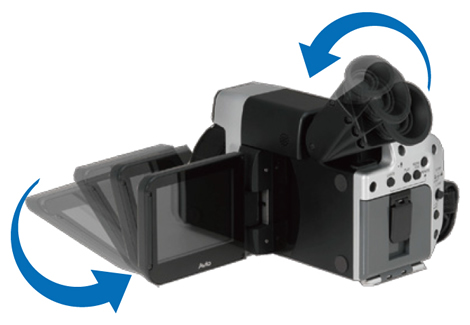

- Lightweight and compact body (battery operated) weighing only 1.5kg (including a battery pack, excluding a protection shield)

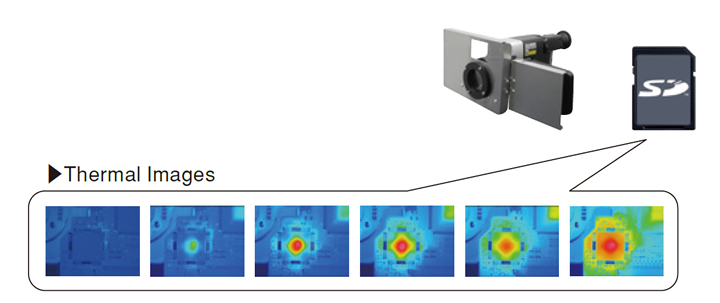

- Thermal movie data can be recorded directly to SD card at max speed 10Hz only by the camera.

Therefore, required data can be recorded in a short time without PC. In addition, the Thermal movies data is analyzable by the dedicated standard software "InfReC Analyzer NS9500 Professional" later.

- A tilting LCD monitor enables images to be captured at various angles.

- "Full-auto function" allows temperature scale and focus to be adjusted simultaneously.

Folding protection shield included as Standard Accessories

Imaging is possible while assuring the safety of the operator from intensive radiant heat.

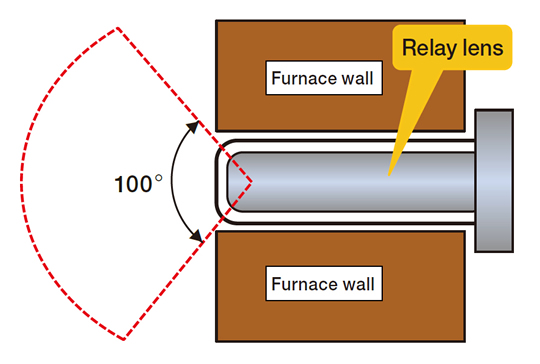

Combination with relay lens insertable in the furnace is available (optional lens)

A wide angle thermal image shooting (up to 100°) is available by inserting "custom-made" relay lens into furnace call hole.

-

- To open .pdf documents, you will need the latest Adobe Acrobat Reader software.

Download Adobe software from left.

If you cannot open the document on your web-browser,

right-click the link and choose option 'Save Target As' to download the pdf into your local storage medium, first.

Then, launch the saved file from your storage device (i.e. HDD of your PC etc.).

- • Specifications and outline on this page are subject to change without notice for improvement.

- • Company names and commodity names are trade names or registered trade marks of each company.

- • Nippon Avionics Co., Ltd. will not be responsible for any damage of infrared detectors due to incoming strong light (e.g. laser) through lens(es).

- • This product is subject to Japanese Export Control Law. Depending on its destination, prior assessment and authorization may be required. When exporting from country of initial purchase destination, please be sure to follow that country's export regulations as it may require an export permit beforehand.