Inspection System for Corrosion Inside the Utility Piping

Hitachi Plant Engineering & Construction Co., Ltd. has developed a basic technology to easily inspect inside of the utility pipings for corrosions using TVS.

Generally speaking, there are two methods to inspect inside of piping; destructive testing, whereby inspection is made after cutting the pipe, and non-destructive testing, whereby inspection is made using ultra-sound or X-ray without cutting the pipe. Under the destructive method, operation must be stopped for inspection. Under the ultra-sound method, measurement must be made at multiple points resulting in long inspection hours. Under the X-ray method, measuring equipment is big and a special skill by a qualified person is required.

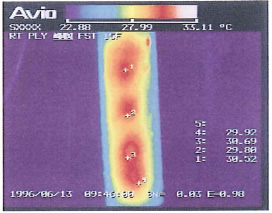

On the other hand, under the non-destructive inspection method by

TVS, a heat resistant body is attached on the external surface of the

pipe as shown in Fig.1 , then the entire heat resistant body is heated

by a sheet heater, and the cooling process after removing the sheet

heater is monitored by TVS. As the cooling speed of the corroded

section surface is slower than that of the normal section, the

corrosion can be detected as a temperature difference as shown in

Photo 1. Fig.2 is the pipe used for experiment, and Photos 2∼5 are

thermal images of the inspected pipe.

- Photo1:Thermal image (using TVS-2300MkII ST)

- Fig.1:Easy diagnosis of piping by TVS.

- Fig.2:Experimental pipe.

- Photos 2∼5:Result of applying the experimental pipe.

A similar inspection has been implemented in the past. But it was difficult to detect corrosion because the temperature change of the pipe was too fast. Hitachi Plant solved this problem by employing a special heat resistant body which delays the temperature change.

Under this inspection method, inspection area as wide as approximately 200 times of the ultra-sound inspection was made possible, and inspection time was also reduced by approximately 30%.

Hitachi Plant is currently applying this inspection technology in the field to accumulate inspection data by the real pipings.

- *Material supplied by courtesy of Hitachi Plant Engineering & Construction Co., Ltd