Quality Control for Blow Molding (Plastics Forming Process)

In blow molding, preforming material, called a parison (which has a original shape of tubes or pipe, peculiar to brow molding), is inserted into a mold, and high pressure air is blown into the parison to force it to press against the inner wall of the mate (or split) mold.

Today, TVS is widely used for quality control on the production of plastic (PET) bottle, which is major product by blow molding, satisfying the demand for efficient supply in stable quality, especially when the consumption of soft drink peaks in summer.

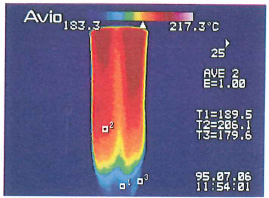

Temperature Distribution Measurement of Parison

Whether the temperature distribution of parison heated for blow

molding is uniform can be checked by TVS.

Blowing parison of nonuniform temperature distribution produces

defective products with nonuniform thickness and leads to complaints such as leaking contents or easy breakage.

- Temperature Distribution Measurement of Parison

(by TVS-110)

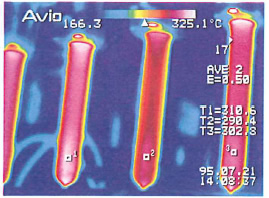

Also,in molding method to blow multiple parisons simultaneously, TVS can be used to check if there are large temperature differences among the parisons.

- Simultaneous Comparison of Temperatures of Multiple

Parisons

(by TVS-110)

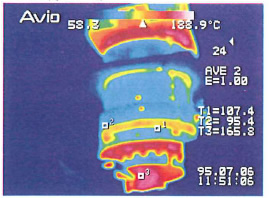

Temperature Measurement of Heating Cylinder and Die

TVS can be used to verify whether specific temperature differences are maintained between heating cylinder and front, middle and rear portions of die, to ensure smooth blow molding process.

- Temperature Measurement for Die

(by TVS-110)